Kitchen-Hood Ventilation Designing

Kitchen-Hood Ventilation Designing

Buildings with Kitchens

1. Hotels

2. Restaurants

3. Hospitals

4. Canteens

5. Retail Malls

6. Residences

7. Jails etc.

Basic purpose of kitchen ventilation

- To provide a comfortable environment in the kitchen.

- to ensure the safety of the people working in the kitchen and other building occupants by:

- Effective removal of effluents which may include gaseous, liquid and solid contaminants produced by the cooking process and products of fuel and food combustion.

- Effluents con be life threatening and flammable

Types of Hoods

1. Wall type hood

2. Island type hood

P= L+2W for wall type hood

P= 2L+2W for Island type hood

KITCHEN HOOD SYSTEM

An exhaust hood

- The centre piece of any kitchen ventilation system (KVS)

- Not just a sheet metal box but a critical component is a well engineered system

- Much greater awareness today about the need for an effective KVS

- Issues are health, safety, efficiency and energy savings

Exhaust Hoods

- Type 1 - for removing grease & smoke : used for cooking appliances

- Type 2 - for steam, vapour, heat & odour when grease is not present : used for diswashers, steam tables etc.

Basic styles of type 1 hood

- Wall mounted canopy

- Single island

- Double island

- Back shelf or proximity

- Pass over

- Eyebrow

Hood Styles

Wall canopy hood

- Cooking appliance placed against a wall

- Minimum air flow requirement

- 3" builts in gap between hood & wall

- Three finished sides

- Less susceptible to cross drafts

- Minimum overhang requirement : 6" on sides and 6" - 12" in front for full captue

Single island hood

- Cooking appliance/s (row) placed in the middle ( not against all )

- Four finished sides

- More susceptible to cross drafts

- Recommended overhang : 12" on all 4 sides

- Baffle filters in "V" configuration

Double island hood

- Double row of appliances placed back to back

- two wall canopy hoods placed back to back

- Recommended overhang : 12" on all 4 sides

Basic styes of type 2 hoods

- Oven hood

- Condensate hoods

Type 2 hood - Condensate hood

- Removal of hesat, odour and omisture

- Condensate baffle and gutter to condense moist air and drain the water

- Used over diswashers

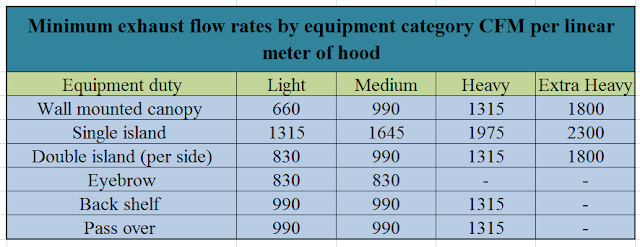

Exhaust flow rate

- Calculation of proper exhaust flow rate is very critical for effective operation oa a KVS

- The upward velocity o fthe effluent thermal currents is mainly a function of the temperature of the cooking surface and varies from 16FPM over steam equipment to 160 FPM over charcoal Broilers.

- Appliances categorized in 4 groups by cooking duty

Appliance duty category

- For a combination of appliances in a row under a single hood, the flow rate is based on the heaviest duty appliance unless the hood design permits different rates over different secions of the hood.

CFM = 150xP for Medium cooking

CFM = 100xP for Light cooking

CFM = 100xP for Light cooking

- Exhaust/makeup air 1500-2200 /fpm duct velocity

- Duct to be terminated 40" above the roof

- Cleanouts to be provided at the base of riser and every 20 feer

- Duct sheet metal gauge

2. 18ga. 304 S.S

- Hood construction 18ga. minimum

- Black steel duct is used all kitchen ducts (Hood) S.Steel duct is used for laundry exhaust.

- Stainless steel

304 for this type is used for hood

316 & 318L for special & pure stainless steel for operation theater in hospitals.

No comments